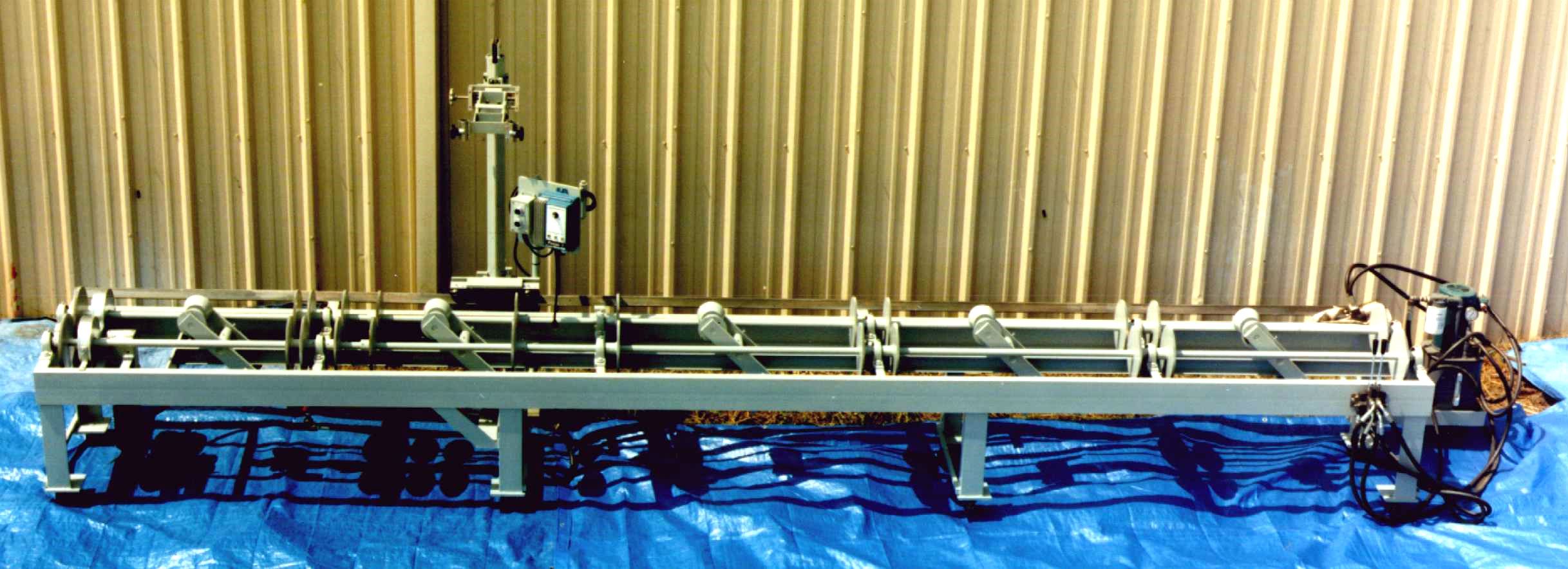

Burnoff Table

BEC Model 2-30 (BOT)

BEC Model 2-30 (BOT)Burnoff Table 2 – 30” Capacity

The BEC Burnoff Table accommodates 2 through 30” pipe. It features variable speed rotation with hydraulic actuated roller lift. The table is coupled with a rack system for torch mount that is calibrated within .030 tolerance for square and consistent cuts on production runs as well as allowing the operator to make longitudinal cuts as well. Variable speed rotation produces exceptionally clean and smooth cuts on all sizes and wall thickness of pipe. The BEC Burnoff Table’s hydraulic-actuated roller system provides for ease of positioning for initial cuts as well as repositioning pipe for subsequent cuts. This feature also makes the burnoff table an excellent fitup table for pipe and rounds. It can also be used as a weldout table in place of power rolls

Features:

|

Options Available:

|

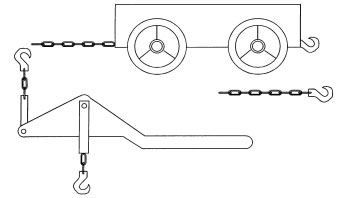

Hold Down Tool

The BEC Model HDT-3 provides a simple and direct means of securing round loads to the BEC Pipe Rolls. This attachment provides stability and consistent slip free movement on eccentric loads.

The Hold Down Tool is the perfect companion for Power Rolls and Burnoff Table operations using BEC equipment.

All wheels on the BEC Hold Down Tools are equipped with sealed needle bearings for long life under rigorous conditions. Wheels are available in steel, rubber and polyurethane.

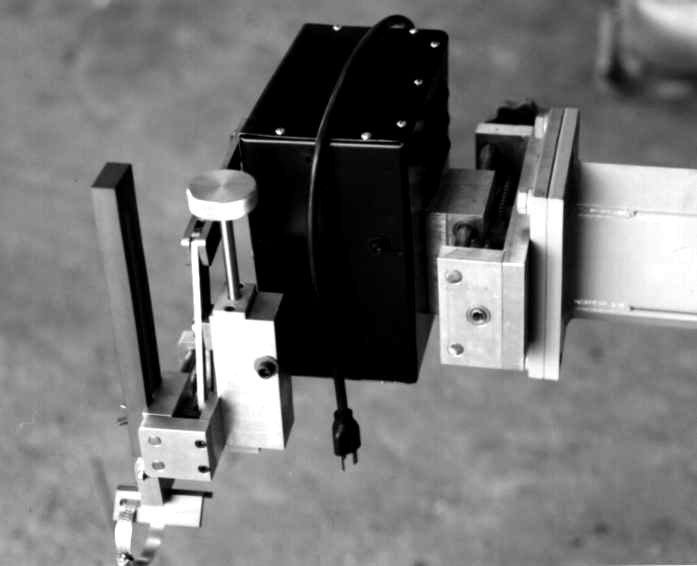

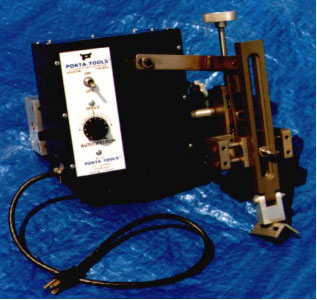

Durango Linear Oscillator

The Durango Linear Oscillator provides a smooth and consisten

The Durango Linear Oscillator provides a smooth and consisten t weld bead from root pass through cap pass. This is the ideal tool for automating your circumferential, straight seam and multi-pass overlay welding. This tireless alternative to manual welding can easily double or triple your production rate, reduce welder fatigue and produce consistent quality welds. The standard oscillator has adjustable right/left dwell, adjustable speed potentiometer and adjustable weave width with approximately 25 pounds torch holder capacity.

t weld bead from root pass through cap pass. This is the ideal tool for automating your circumferential, straight seam and multi-pass overlay welding. This tireless alternative to manual welding can easily double or triple your production rate, reduce welder fatigue and produce consistent quality welds. The standard oscillator has adjustable right/left dwell, adjustable speed potentiometer and adjustable weave width with approximately 25 pounds torch holder capacity.Used in conjunction with the BEC Manipulators and with matching crossfeed slide assemblies, this oscillator can semi-automate your MIG, TIG, and Sub-Arc welding shop or department.